Pressure Reducing Vavles

It is easy to use, handy and wide choice under any circumstances with various types of models.

It is easy to install by diverse change on requests from the field such as union type and socket type which are convenient for plumbing work.

It can avoid malfunction from foreign object by installing internal screen.

It resolved disadvantage of assembled reducing valve by simplifying connection and separation of water angle valve and reducing valve and is easy to maintenance management.

-

PRV-102

- -

PRV-202

Pressure Indicated Type -

PRV-602

- -

PRV-702

-

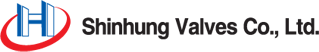

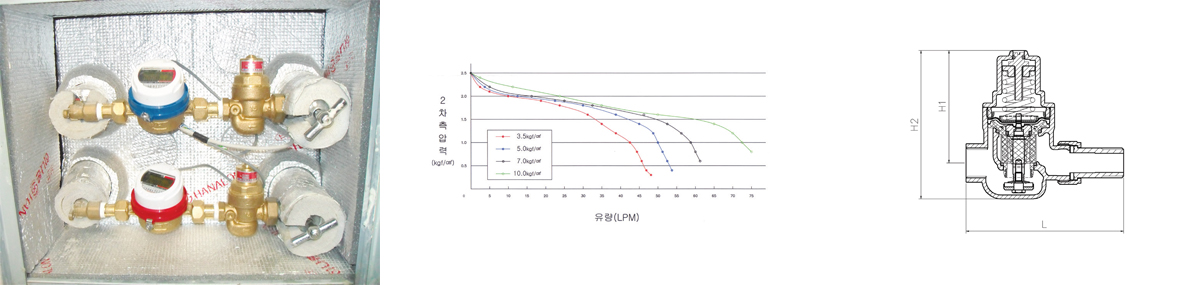

Dimension

| Model | SIZE | L | H1 | H2 | PT |

| PRV-102 | 15A | 110 | 90 | 120 | 1/2 |

|---|---|---|---|---|---|

| 20A | 110 | 90 | 120 | 3/4 | |

| PRV-202 | 15A | 110 | 90 | 120 | 1/2 |

| PRV-602 | 15A | 135 | 90 | 120 | 1/2 |

| PRV-702 | 15A | 110 | 90 | 120 | 1/2 |

Specification

| Model | PRV-102 | PRV-202 | PRV-602 | PRV-702 | ||

| Applied Fluid | Water | |||||

|---|---|---|---|---|---|---|

| Applied Pressure | MAX, 1MPa | |||||

| Applied Temperature | MAX. 80℃ | |||||

| Scope of Pressure Control | 50~500 KPa | |||||

| Minimum Operating Pressure Differential | 50 KPa | |||||

| Pressure Test | 2MPa | |||||

| Main Material |

BODY | CAST BRASS(NPB / DR) | ||||

| COVER | CAST BRASS | |||||

| DIAPHRAGM | E. P. D. M. | |||||

| SEAT | STS 304 | |||||

| SCREEN | STS 304 | |||||

Installation Method

Reducing valve should be installed after removing foreign object clearly from pipe.

It can be operated well with prevent turbulent phenomenon by place straight throat at front and backside of valve.

Manual shutoff valve should be installed in front of reducing valve for the emergency

Pressure Control Method

Pressure valve would be released with previously set of secondary spindle pressure as request of orderer so that it has no need to be set pressure particularly, but in case of adjust with necessary, secondary

pressure will be high with turning adjust volt (adjust handle) as clockwise rotation, and will be low with turning adjust volt (adjust handle) as counterclockwise rotation.

pressure will be high with turning adjust volt (adjust handle) as clockwise rotation, and will be low with turning adjust volt (adjust handle) as counterclockwise rotation.

Fault Diagnosis and Treatment Method

| Problem | Cause | Treatment method and measu |

| Low volume of water supply | Strainer is plugged up | Clean the strainer in pipe and valve |

|---|---|---|

| Disorder of pressure control of valve | Readjust pressure | |

| The secondary spindle pressure is low |

The first spindle pressure is low | The first spindle pressure should be higher than the secondary spindle pressure |

| Disorder of control spring | Replacement of spring after inspecting damage of spring | |

| A fluid does nor flow | Direction of the installation is wrong | Tune direction of a fluid to direction of an arrow |

| Set pressure is low or control bolt get loose | Readjust pressure | |

| Rising of the secondary spindle pressure |

Disorder of diaphragm | Replacement after inspecting damage |

| Insertion of foreign object in Disc Seat | Removal of foreign object in Disc Seat after inspection | |

| Damage of Disc Seat | Replacement of Disc Seat after inspection. For damage | |

| Abrasion of O-Ring | Replacement of O-ring after inspecting for damage and abrasion |

|

| Leaking of Spring case | Damage of diaphragm | Replacement after inspection for damage |

| Damage of spring case | Replacement after inspection for damage |